[2007-12-12] Undercarriage inspection mirror

This junket began with a side view mirror from an automobile, obviously dislodged in a crash, that I found in the street a couple of years ago. The mirror itself was intact when I found it, as well as most of the plastic frame it seemed to have been manufactured in. As is my rule for junkets, I selected the mirror from my junk bin at random, and meditated long and hard about what to do with it. I thought briefly about cutting it or breaking it up to make some mirrored object, but then remembered one of the fundamental principles of junkineering, which is to preserve value as much as possible--the mirror would be more useful as a whole. I then brainstormed places where I might use a small mirror and finally remembered seeing U.S. Customs agents inspecting automobile undercarriages at the Mexican border using a special mirror about the size and configuration of a broom, and thought it might be cool to have one of my own (not that I have any real use for it). Jennifer insists I built it for looking up women's skirts. One-two-free-fo-FIF! Seriously, though--it's a bit conspicuous for that purpose!

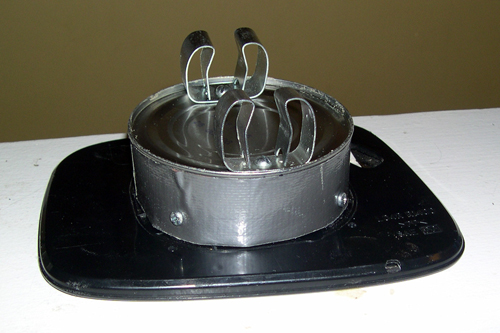

So the mirror's plastic frame included 4 molded tabs on the reverse side that could be readily exploited to mount the whole mirror assembly, and doing so was simply a matter of finding a suitable cylindrical bit of junk that matched the diameter of the circle on which they were arranged. A bit of experimentation produced a round Piroulines tin. The lid was too large but the can itself fit over the tabs just perfectly. The bottom of the can was removed with tin snips and ~1cm "flaps" cut in the raw metal edge and folded over, into the can, to strengthen the edge and make it safer to handle. Two broom clips from the hardware bucket were attached to the can's bottom using screws, nuts, and flat and lock-washers as shown. The can-bottom assembly was then fit over the plastic tabs molded on the backside of the mirror and secured by first drilling a subdiameter hole through the folded metal edge of the can and into each of the four plastic tabs, and then driving in short wood screws. The printing on the outside of the can was obscured with a turn of duct tape, solely for cosmetic reasons.

All I needed now was a handle. Once again my prodigious junkpile rose to the occassion, yielding a piece of 3/4" EMT conduit that was bent into a huge snowshoe shape while I was learning to use the conduit bender to make my MASC chair. I used a manual tubing cutter to cut the snowshoe right in the middle; one of the remaining halves was the perfect shape to mount and use the mirror assembly, as shown below. It should be noted that the orientation of the broom clips on the mirror assembly was chosen to maximize the length of the oblong mirror in the plane of incidence and reflection when the inspection mirror is used as shown.

last modified 2007-12-14